Because using what you already have is the most eco-friendly choice. We aim to be your second choice. That's why we produce the second most sustainable jeans in our own factory in Saigon, Vietnam.

Part of the change

The jeans industry is notorious for its significant negative impact on both people and the planet. The production of denim jeans involves extensive water consumption, the use of harmful chemicals, and the generation of substantial waste. This is exactly what we want to change.

Materials that matter

What makes a product sustainable depends on a long list of aspects. Some are in your hands, for example how often you wear your clothes and how well you care for them. Other aspects are in our hands – such as the production methods and materials.

While we like to test innovative materials, there are three all-time favorites we continuously use in our products: organic cotton, hemp and Tencel™. But every material comes with its own set of chances and challenges. To understand our material choice better, we have to get a little more technical. Ready to learn more?

Organic Cotton

At DAWN, we prioritize sustainability without compromising on style or comfort. Our organic cotton collection embodies this commitment. Organic cotton is grown without the use of synthetic pesticides and relies on sustainable agricultural practices. This approach leads to healthier ecosystems and improves the soil quality. But there’s more!

Tencel™

Our summer styles made from Tencel™ bring you the perfect blend of summer and comfort. It gives clothing a silky character, drapes beautifully, and feels exceptionally pleasant on the skin as it is incredibly soft and lightweight. No wonder, it’s our absolute summer bestseller. But do you know how the fiber is made?

Hemp

Hemp is a fiber with a rich history as it was one of the first materials used for clothing. Today it celebrates a comeback as more and more brands start looking into the natural material again. Compared to other crops, hemp plants grow quickly and require minimal pesticides and herbicides.

Innovative technologies

There are different technologies to achieve different shades of blue from the indigo denim fabric. This presents us with the challenge of finding technologies that are as sustainable as possible and go easy on people and resources. Currently, we are testing the following technologies for the production of your jeans.

Earth Dye from Near-Chemica

In our quest for more sustainable production techniques, we have introduced natural dyes sourced ethically from the earth. The dye pigments, formed around 4.5 billion years ago from galactic collisions, are now used to color our garments in a particularly gentle way. Our Earth Dye Collection items are colored with natural earth dyes made from pigments derived from minerals, stones, and soils, making them unique and completely safe for the environment and your skin.

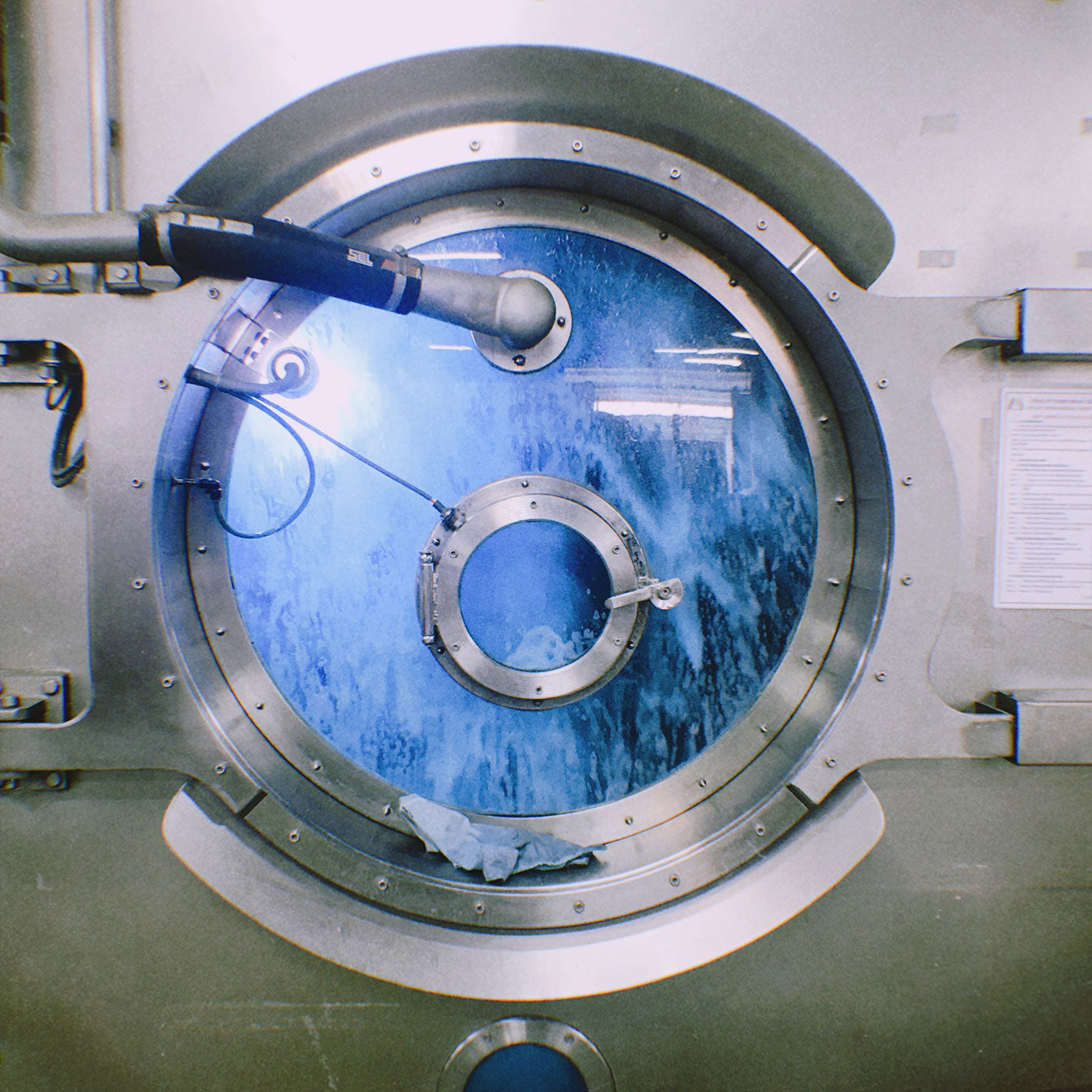

E-Flow: Jeans with Up to 90% Fewer Chemicals

In order to give jeans certain properties, like making them softer or achieving a washing effect on the jeans, a lot of chemicals, water and energy are used in conventional jeans production.

Jeanologia's E-Flow technology takes a completely different approach: Nanobubbles – tiny air bubbles – apply the necessary chemicals to the fabric. Not only does this cut water consumption by up to 95% and energy consumption by up to 40%, but it also cuts chemicals by 90%.

Ozone: Bleaching Without Chemicals

One resource of which a great deal is consumed in jeans production is water. In traditional jeans production, the dark blue indigo fabric is washed out of the fabric in multiple washes with many chemicals until the desired shade of blue is achieved.

To reduce water consumption and eliminate the use of chemicals, the ozone technology of Jeanologia's machines uses the natural bleaching properties of ozone gas. In this process, oxygen from the air is converted into ozone gas and then reconverted after the bleaching process. In this way, a lighter blue denim can be achieved completely without the use of chemicals and up to 65% of the water in the bleaching processes can be saved.

Laser Technology: Effects Without Manual Labour

Lighter areas that create the popular worn look of jeans are worked into the fabric by hand in traditional jeans manufacturing. Not only is this very time- and labor-intensive, but it also uses a lot of chemicals. Instead of working design highlights into the denim fabric by hand, laser technology makes it possible to create that special look without any manual labor at all. It uses light and heat to process the surface of the fabric, revealing the white core of the yarn.

Our initiatives

In addition to our own factory in Vietnam and our innovative production processes, we have launched even more projects to live our values of fairness and sustainability. Here you can find an overview of all our projects and initiatives.

Art on Broken Pieces

With our upcycling project, Art on Broken Pieces, we give new life to jeans with minor production flaws. Despite our careful and meticulous work in our factory in Saigon, Vietnam, small production errors are sometimes unavoidable. Art on Broken Pieces was born from the desire not to discard jeans with minor imperfections. A small stain, a tiny tear, an uneven seam—is that really enough to throw away a product? We think not.

Our unique solution is Art on Broken Pieces. We transform products with minor flaws into special, one-of-a-kind pieces through careful hand embroidery and patches.

Retraced: It all starts with Transparency

Our products feature a QR code from Retraced, providing comprehensive insights into our supply chain. This tool allows both retailers and consumers to trace the origins of our products, access certificates, and learn more about our suppliers, making it easier to understand the values behind our brand. Transparency is more than just a map—it's about getting personal with our entire supply chain. Though challenging, we strive to meet our farmers face to face.

PETA-Approved Vegan Jeans

At DAWN, we believe in making jeans with minimal environmental impact. In 2019, we went completely vegan by replacing leather patches with FSC-certified paper. Our commitment ensures that no animals are used in the production of our jeans, and none of our products are tested on animals. We also do not use any adhesives of animal origin. Therefore, we can confirm: Our jeans are 100% vegan.

Are our jeans PETA certified?

Yes, our jeans are certified vegan by PETA! The PETA certificate is based on company self-disclosure and an annual certification fee of 2,500€.

11 for 1: Creating a greener world, one garment at a time

Each purchase of our Environmentalist Tree T-Shirt translates into 11 trees planted in Vietnam, showing our commitment to action over words. Partnering with One Tree Planted, we aim to restore ecosystems threatened by fires, the palm oil industry, and illegal mining.