OUR FUTURE IS TRASHION

What if waste wasn’t the end, but the beginning? DAWN has made it its mission to close loops.

Trash,

but make it fashionable.

This is PIW undyed. Post-Industrial Waste. Fabric scraps that never made it to a hanger, rescued before ending up in landfill.

At Recover™ Vietnam Recycling hub, we take these leftovers and turn them into denim with character. Slightly more rigid, a bit drier to the touch, less stretch but more attitude and with less reliance on virgin resources.

Closing the Loop Collection

One loop

at a time ♻️

We at DAWN bring denim made from production waste like offcuts and leftover materials into the store - This is part of our principle “Closing the Loop.”

Trash that would otherwise pile up is turned into high-quality DAWN jeans.

Across our entire value chain, we continuously examine how resources, by-products and waste can be fed back into the loop - both during production and after a product has been used by our customers.

Closing the loop,

literally.

Closing the loop, literally.

Every year, tons of denim never make it past production. We take Post-Industrial Waste (PIW), recycle it, and turn it into new DAWN pieces instead of wasting it.

Less waste. More recycled denim. That’s PIW. 20% of waste used in our denim, means roughly 20% less reliance on virgin fibers.

Post-Industrial Waste: Rethinking production leftovers

Post-industrial waste is a core element of DAWN’s circular strategy. Together with our partner Recover™, local production leftovers are collected and processed into new yarn. This yarn is then used to create new DAWN products.

Discover denim made from recycled fibres

Pre-Consumer Waste: Flaws that gain character

Some products are already finished but can’t be sold regularly due to minor imperfections.

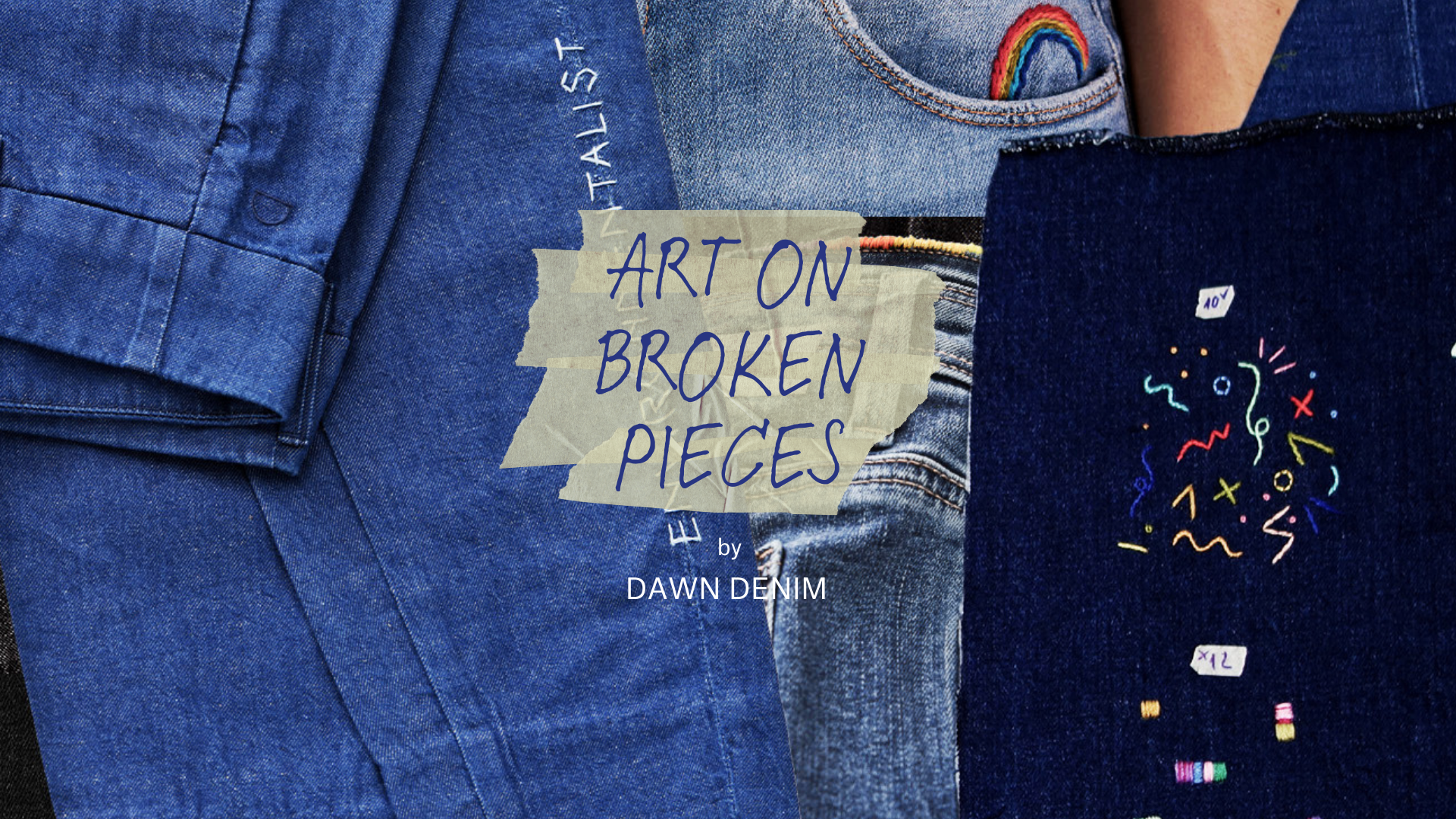

Our response: Art on Broken Pieces.

Instead of discarding them, artists enhance each piece with individual embroidery.

Every pieces is one of a kind – handcrafted, creative, and consciously imperfectly.

Discover Art on Broken Pieces

Post-Consumer Waste: When an end becomes a beginning

For us, a products that has reached the end of its original life is not waste. It's the starting point of repair, upcycling, or reintegration into the material cycle.

This is where we work to close the loop.

We seal the deal.

DAWN is part of the Denim Deal– an industry-wide initiative in which brands and producers commit to using at least20% post-consumer recycled cotton.

Our goal: alarge-scale proof-of-concept project by 2026thatdemonstrateshow true circularity can be achieved even within complex, global value chains.

How the loop works – step by step

#1

Preparation & processing

Once the material waste arrives, larger textile pieces are prepared first: trims such as buttons and

zippers are removed, and the textiles are cut into smaller, manageable pieces.

These pieces then go through a mechanical shredding process, designed to pull the material back into individual fibers. This method relies on physical processing – not chemical dissolution – and uses minimal water and additives.

#2

Sorting & quality control

After shredding, the recovered fibers are baled and

prepared for transport.

They are fully traceable and meet the required quality standards for spinning and textile production.

#3

New yarn. New fabric. New life.

The recovered fibers are then supplied to textile partners, including brands like DAWN.

There, they are spun into new yarns and woven or knitted

into fabrics. Turning waste into denim, once again.

Are you still recycling – or already closing the loop?